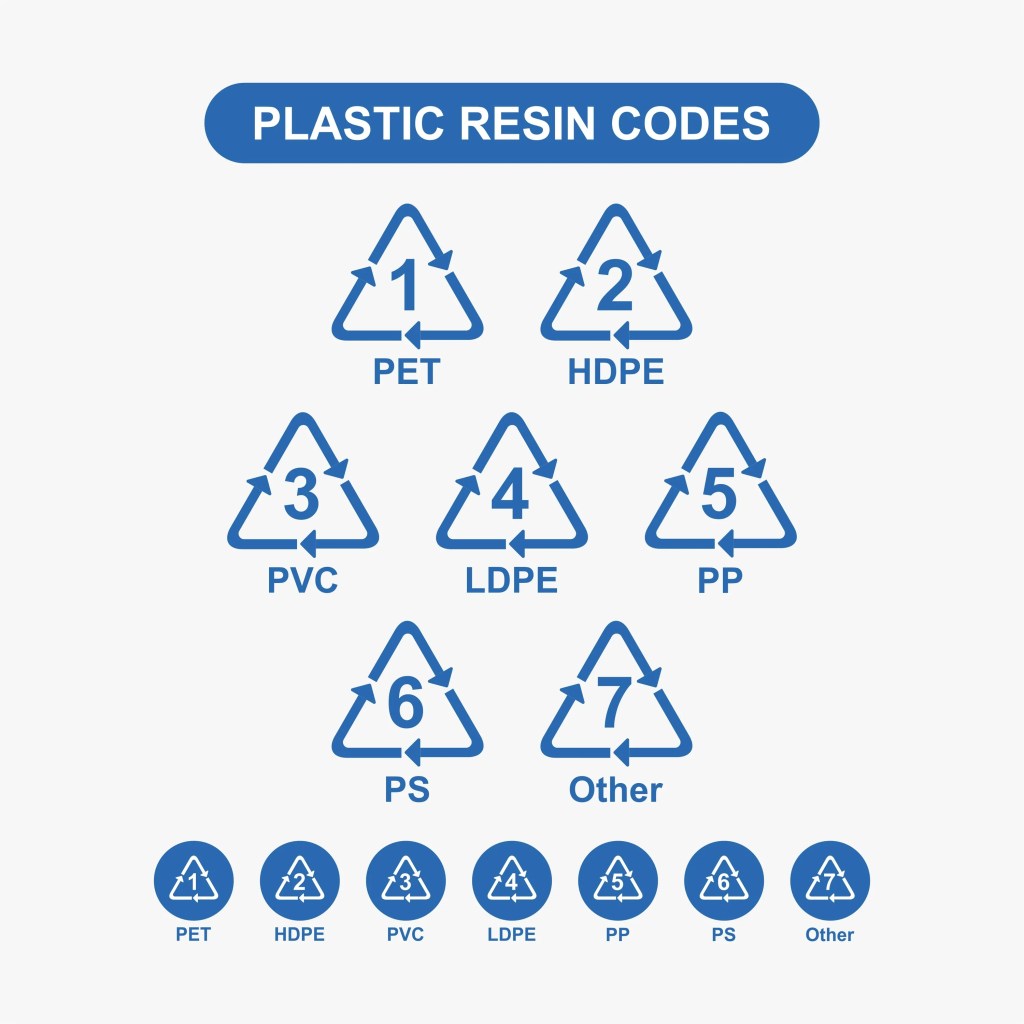

A danger to life as we know it is caused by our environmental impact of trash! Did you know there’s a pile of garbage twice the size of Texas floating between Hawaii and California? Majority of this garbage is made up of plastic, a lot of which has direct harmful effects on wildlife and the Earth’s natural processes. Many companies are putting forth efforts toward better recyclability by labeling bottles based upon plastic types. It is very likely that you have never heard of plastics being labeled by their compositions. There are 6 main plastics that recycling aims to identify and repurpose. Polyethylene Terephthalate, High Density Polyethylene, Polyvinyl Chloride, Low Density Polyethylene, Polypropylene, Polystyrene, and other, which is a mixture of different plastics. To make life easier, those hard to pronounce names are identified as plastic type 1,2,3,4,5,6, and 7, respectively. Type 1 will usually be found in drinking bottles and food jars. Type 2 is shipping containers and house cleaning bottles. Type 3 in pipes, fencing, and medical tubing. Type 4 is often found in shrink wrap and newspapers. Type 5 would be found in medicine bottles, bottle caps, and automotive parts. Type 6 should be found within disposable cups and food containers. Last but not least, type 7 would be a mixture of the previous 6 or an unnamed type of plastic. If you take a plastic container in your home and check it for its plastic type you may find it enshrouded in a triangle made of arrows, the symbol for recycling:

My local recycling facility happens to be the Sims Municipal Recycling Plant in Brooklyn, NY. There they use a technique to sort plastics with the aid of infrared spectroscopy. This allows items along a conveyor belt to be scanned at a rate of about 10,000 per minute. The infrared imaging technique scans the plastic item, and analyzes it for its chemical makeup. The chemical makeup is then matched to one of the seven above plastic resins, those of the same type of resin are grouped together. The process of recycling becomes much more difficult when the sensor can not identify a material or the container is obstructed by something such as a product label. Through experimentation I discovered my pre-workout container by the brand Optimum Nutrition had a different plastic on its label versus its bottle. The infrared sensor can only scan about one micrometer deep, or about the size of a bacterial cell. This very fine sensing depth leaves the sensor unable to penetrate most product labels to discover the container underneath. Once a scanner sees this bottle on the conveyor belt it will identify the entire container solely by the plastic label, and through my infrared experimentation it was shown that it is possible to have a container be composed of different plastic resins. This makes the recycling process much more prone to mis-sorting of recyclables which in turn reduces the efficiency of the recycling effort as a whole. From this experimentation and data I encourage companies to seek ways to improve the recyclability of their products. Through methods such as ensuring an item, regardless of its number of components, is composed of the same plastic resin. That would allow the product to be recycled at near 100% efficiency. Manufacturers could also ensure that each individual plastic component of their products is labeled with the proper plastic resin identifier to allow more ease in the sorting process. Small steps to be taken that would change the world we live in and provide for a safer future for us and all those who are to come after us. Save Now, Save the Future, Save our Planet